Difference between revisions of "Fencing Draft:Safety Tests"

Jump to navigation

Jump to search

| (23 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | + | <div class='rulesNumbering' style="counter-reset: page 15"> | |

| − | Penetration-resistant material, masks, blade flexibility and rubber band gun ammunition must be tested by an authorised marshal at least every two years, separate to inspections at training and events. | + | ==General== |

| + | #Penetration-resistant material, masks, blade flexibility and rubber band gun ammunition must be tested by an authorised marshal at least every two years, separate to inspections at training and events. | ||

| + | #Tests to penetration-resistant material must be made on the object itself, not a swatch of identical material, unless such a swatch undergoes the same stresses as the garment by being sewn onto the inside of a garment, as the swatch will not otherwise have undergone the same stresses over time. | ||

| + | |||

==Penetration-resistant material== | ==Penetration-resistant material== | ||

Penetration-resistant material is tested using a drop tester that meets SCA standards. | Penetration-resistant material is tested using a drop tester that meets SCA standards. | ||

| − | The specifications for creating a drop tester are available in [https://www.sca.org/ | + | The specifications for creating a drop tester are available in [https://www.sca.org/wp-content/uploads/2020/04/FencingMarshalsHandbookApril2020.pdf Appendix 3 of the Society Fencing Marshals' Handbook]. |

The drop tester enables marshals to consistently test material by dropping a known weight a known distance, creating a known impact. | The drop tester enables marshals to consistently test material by dropping a known weight a known distance, creating a known impact. | ||

| Line 10: | Line 13: | ||

===Drop test procedure=== | ===Drop test procedure=== | ||

====Equipment==== | ====Equipment==== | ||

| + | [[File:Drop_tester.jpg|frame|Figure 6. Drop-tester]] | ||

To conduct the test you need all pieces shown in the figure, including: | To conduct the test you need all pieces shown in the figure, including: | ||

*a guide tube | *a guide tube | ||

| Line 16: | Line 20: | ||

*two hose clamps | *two hose clamps | ||

*a screw driver or nut clamp to tighten the hose clamps. | *a screw driver or nut clamp to tighten the hose clamps. | ||

| − | |||

====Procedure==== | ====Procedure==== | ||

| Line 22: | Line 25: | ||

#Set the flange thread side up and lay the test fabric over it. | #Set the flange thread side up and lay the test fabric over it. | ||

#Fit the first hose clamp over the fabric and flange, and pull the fabric tight as you push the clamp down. Tighten the clamp. | #Fit the first hose clamp over the fabric and flange, and pull the fabric tight as you push the clamp down. Tighten the clamp. | ||

| − | #Fit the second clamp below the flange so that it is touching the first. Make sure the fabric is | + | #Fit the second clamp below the flange so that it is touching the first. Make sure the fabric is firmly secured. |

#Place the guide tube vertically in the centre of the fabric. | #Place the guide tube vertically in the centre of the fabric. | ||

| − | #Insert the probe into the guide tube, lined up to the mark to drop it from. | + | #Insert the probe into the guide tube, lined up to the mark to drop it from the prescribed height. |

#Drop the probe. | #Drop the probe. | ||

#Examine the fabric. | #Examine the fabric. | ||

| − | ## | + | ##For multiple layers, if the probe has penetrated anything below the top layer of fabric, the material fails. |

| − | ## | + | ##For a single layer garment, if the probe penetrates that layer, the material fails. |

#If the probe does not punch through, check that the clamps are still secure and that the fabric did not slip. | #If the probe does not punch through, check that the clamps are still secure and that the fabric did not slip. | ||

#If the marshal is satisfied, the material passes. | #If the marshal is satisfied, the material passes. | ||

===Exemptions=== | ===Exemptions=== | ||

| − | The following materials are known to pass these tests when new: | + | #The following materials are known to pass these tests when new: |

| − | *ballistic nylon rated to at least 550 Newtons | + | #*ballistic nylon rated to at least 550 Newtons |

| − | *commercial fencing clothing rated to at least 550 Newtons | + | #*commercial fencing clothing rated to at least 550 Newtons |

| − | *mail made of welded or riveted steel rings that will not admit a 5/32 inches (4 mm) diameter probe. Rings no greater than 0.155 inches (4 mm) in internal diameter made of wire no less than 0.020 inches (0.5 mm) thick meet this requirement | + | #*mail made of welded or riveted steel rings that will not admit a 5/32 inches (4 mm) diameter probe. Rings no greater than 0.155 inches (4 mm) in internal diameter made of wire no less than 0.020 inches (0.5 mm) thick meet this requirement |

| − | These materials only need to be tested at the marshal's discretion. | + | #These materials only need to be tested at the marshal's discretion if newly purchased. Ballistic nylon and commercial fencing clothing rated to at least 550 Newtons must be tested every two years, as they can degrade with use. |

==Blade flexibility== | ==Blade flexibility== | ||

| Line 49: | Line 52: | ||

==Rubber band gun ammunition tests== | ==Rubber band gun ammunition tests== | ||

===General=== | ===General=== | ||

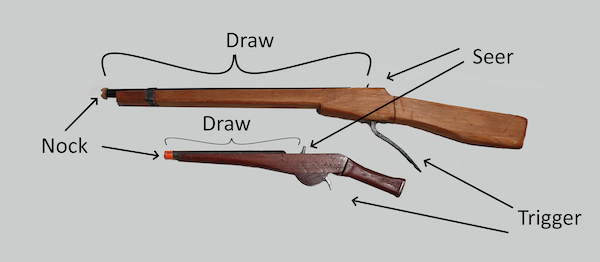

| − | #Rubber band gun ammunition must be tested to ensure it complies with the draw strength requirement of no greater than 13.6 kg (30 pounds). The following test can be conducted using a digital luggage scale, with reference to | + | [[File:Draw_length_of_RBG.png|frame|Figure 7. Draw length of a rubber band gun]] |

| + | #Rubber band gun ammunition must be tested to ensure it complies with the draw strength requirement of no greater than 13.6 kg (30 pounds). The following test can be conducted using a digital luggage scale, with reference to figure 7. | ||

#Ammunition tests must be conducted at a location out of range of other people. | #Ammunition tests must be conducted at a location out of range of other people. | ||

#Marshals and participants in the inspection must wear a face mask. | #Marshals and participants in the inspection must wear a face mask. | ||

| Line 57: | Line 61: | ||

#Using the scale, draw the rubber band all the way to the seer. | #Using the scale, draw the rubber band all the way to the seer. | ||

#Check the weight on the scale to ensure it complies with the rules. | #Check the weight on the scale to ensure it complies with the rules. | ||

| − | + | ||

</div> | </div> | ||

| − | [[Category:Draft Fencing Handbook | | + | [[Category:Fencing Draft Handbook | O]] |

| + | [[Category:Fencing Draft Handbook Logged | O]] | ||

Latest revision as of 09:46, 23 December 2023

General

- Penetration-resistant material, masks, blade flexibility and rubber band gun ammunition must be tested by an authorised marshal at least every two years, separate to inspections at training and events.

- Tests to penetration-resistant material must be made on the object itself, not a swatch of identical material, unless such a swatch undergoes the same stresses as the garment by being sewn onto the inside of a garment, as the swatch will not otherwise have undergone the same stresses over time.

Penetration-resistant material

Penetration-resistant material is tested using a drop tester that meets SCA standards.

The specifications for creating a drop tester are available in Appendix 3 of the Society Fencing Marshals' Handbook.

The drop tester enables marshals to consistently test material by dropping a known weight a known distance, creating a known impact.

Drop test procedure

Equipment

To conduct the test you need all pieces shown in the figure, including:

- a guide tube

- a drop probe

- a 75 mm threaded PVC flange

- two hose clamps

- a screw driver or nut clamp to tighten the hose clamps.

Procedure

- Use a hard surface. Carpet or grass absorb impact and make the test unreliable.

- Set the flange thread side up and lay the test fabric over it.

- Fit the first hose clamp over the fabric and flange, and pull the fabric tight as you push the clamp down. Tighten the clamp.

- Fit the second clamp below the flange so that it is touching the first. Make sure the fabric is firmly secured.

- Place the guide tube vertically in the centre of the fabric.

- Insert the probe into the guide tube, lined up to the mark to drop it from the prescribed height.

- Drop the probe.

- Examine the fabric.

- For multiple layers, if the probe has penetrated anything below the top layer of fabric, the material fails.

- For a single layer garment, if the probe penetrates that layer, the material fails.

- If the probe does not punch through, check that the clamps are still secure and that the fabric did not slip.

- If the marshal is satisfied, the material passes.

Exemptions

- The following materials are known to pass these tests when new:

- ballistic nylon rated to at least 550 Newtons

- commercial fencing clothing rated to at least 550 Newtons

- mail made of welded or riveted steel rings that will not admit a 5/32 inches (4 mm) diameter probe. Rings no greater than 0.155 inches (4 mm) in internal diameter made of wire no less than 0.020 inches (0.5 mm) thick meet this requirement

- These materials only need to be tested at the marshal's discretion if newly purchased. Ballistic nylon and commercial fencing clothing rated to at least 550 Newtons must be tested every two years, as they can degrade with use.

Blade flexibility

To test the flexibility of a blade, follow this procedure.

- Clamp or hold the blade, where it meets the tang, on a rigid surface, such as a table, to ensure it doesn't move at the table end. The rest of blade must extend off the rigid surface so that it is unsupported.

- Hang a 170 gram (6oz) weight 25 mm from the tip.

- If the blade of a dagger flexes at least 12.5 mm (1/2 inch), it meets the standard.

- For a sword used in Fencing Combat, the blade must flex at least 25 mm (1 inch).

- For a sword used in Cut and Thrust Combat, the blade must flex at least 12.5 mm (1/2 inch).

Rubber band gun ammunition tests

General

- Rubber band gun ammunition must be tested to ensure it complies with the draw strength requirement of no greater than 13.6 kg (30 pounds). The following test can be conducted using a digital luggage scale, with reference to figure 7.

- Ammunition tests must be conducted at a location out of range of other people.

- Marshals and participants in the inspection must wear a face mask.

Procedure

- Attach the luggage scale to the rubber band. Switch the scale on.

- Fit the band to the nock.

- Using the scale, draw the rubber band all the way to the seer.

- Check the weight on the scale to ensure it complies with the rules.